Introduction

Which tests are compulsory for cosmetic products before being placed on the EU/UK markets?

Testing represents an important part of a cosmetic product registration process. Cosmetic products have to undergo all the required testing defined in the EU Cosmetics Regulation (EC) 1223/2009 and the UKCR in order to be compliant and more importantly, to prove they are safe for use under reasonably foreseeable conditions.

There are three main types of testing for cosmetic products in the EU/UK.

Testing is usually the most time-consuming part of the cosmetic product registration process, so it is important to have that in mind before starting the compliance process.

The standard tests are as follows:

- Stability and Compatibility tests

- Challenge test (Preservative Efficacy Test, abbreviated PET)

- Microbiological Quality Analysis

BIORIUS provides assistance from A to Z.

Our experts co-ordinate everything with the testing laboratory in the interest of our customers, plus our prices are really competitive!

Which tests are compulsory for cosmetic products? How long does it take to perform them? What are they for?

Let’s see them together in detail:

Stability and Compatibility Tests

The Stability test, including the Compatibility test, is always required. The Compatibility test is not required only if the packaging is completely made of glass.

The in-packaging Stability study is necessary to verify that the product does not deteriorate over time and determine its shelf life. This test is generally conducted over a period of 12 weeks and is performed at 40°C. Sometimes other times and temperatures are also tested in parallel (0°C, 25°C, 50°C at different times/freezing/thawing cycle).

This test therefore verifies that the specifications of the product like the appearance, odour, colour, pH (if applicable) and viscosity (if applicable) remain stable over time and under various conditions. During this Stability test, the Compatibility of the packaging must also be checked. This is why the report must also include packaging parameters over a 12-week period at 40°C, including weight loss and change in packaging appearance.

Challenge test (PET)

If your cosmetic products are part of the cases listed below, then they do not have to undergo the Challenge test (but a Microbiological Analysis may still be required):

- Anhydrous products (or products with low water activity: <0.6)

- Products with a pH value ≤ 3 or ≥ 10

- Products containing ≥ 20% alcohol

- Products containing ≥ 25% aluminium hydrochloride

- Products containing a strong oxidising or reducing agent

- Products containing a polar organic solvent

- Products that cannot be opened (aerosols, airless packaging)

- Single-use products

The purpose of this test is to evaluate the efficacy of preservatives in a cosmetic product. The latter is analyzed in the presence of multiple pathogenic cultures and monitored at 7, 14 and 28 day intervals. The objective is to detect a decrease in pathogens and thus confirm the efficacy of the preservative(s).

Microbiological Quality Analysis

In some cases where a Challenge test is not required, a Microbiological Analysis is still necessary.

The test takes more or less a week.

A product without water cannot support the growth of micro-organisms, but this does not mean that it could not have been contaminated at the beginning of the process through certain raw materials or during the production phase.

Unfortunately, this has already happened with completely anhydrous products and it can be very dangerous for the consumer.

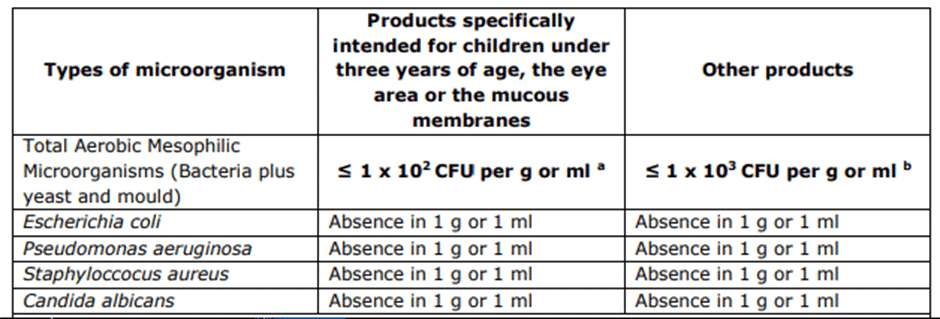

During the microbiological analysis, the “total aerobic microbial count” and the “total yeast and mould count” must be determined, as well as the detection of specific pathogenic germs.

The results must comply with the specifications below:

Finally, Microbiological Analysis is not necessary when:

- The product contains more than 20% alcohol

- The pH of the product is ≤ 3 or ≥ 10

- The product contains a strong oxidising or reducing agent

- The product contains a polar organic solvent

- The product contains ≥ 25% aluminium hydrochloride

- The product is heated for at least 10 minutes at 65°C in the last processing step

- The product successfully passed a Challenge test